Most of us would love to run our homes on solar power - if only it wasn't so unreliable, cumbersome and expensive. But thanks to a pioneering factory in Wales, those objections may not apply for much longer, says David Adam

If you were hunting for the future of solar power, Wales might not seem the most obvious place to look. Yet in a factory in Cardiff, technology that could finally harness the energy of the sun in an affordable way is quietly rolling off the production line. Such claims may sound familiar. Advocates have talked of the potential of solar power to offer clean and green energy for years, yet the technology has remained stubbornly on the fringes. One reason is the cost. Photovoltaic (PV) solar panels to provide an average home with electricity will set you back about £10,000 to £18,000.

Now those behind the Welsh operation think they may have made a crucial breakthrough. Their solar cell works in a different way from most, and is not based on silicon - the expensive raw material for conventional solar cells. G24 Innovations (G24i), the company making the new cells, says it can produce and sell them for about a fifth of the price of silicon-based versions. At present, it makes only small-scale chargers for equipment such as mobile phones and MP3 players. But it says larger panels could follow - large enough to replace polluting fossil fuels by generating electricity for large buildings.

"This has been at the laboratory stage for 18 years and now we are ready to take it into a huge amount of applications," says Clemens Betzel, president of G24i.

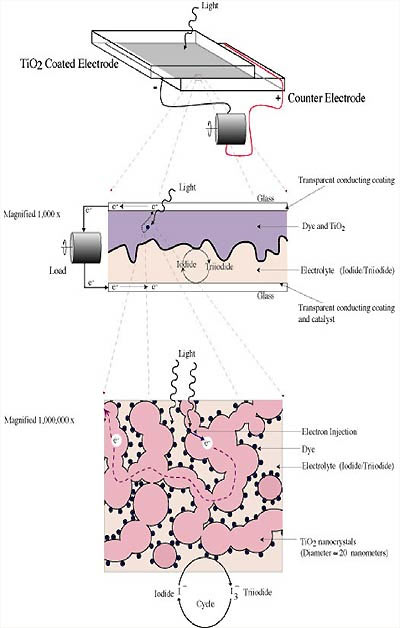

G24i's technology is based on a coloured dye and tiny crystals of titanium oxide - a common pigment in white paint. It exploits a discovery made in 1991 by a Swiss chemist called Michael Graetzel, who found that the combination could be used to copy photosynthesis. When struck by sunlight, the dye spits out an electron, which is immediately captured by the specks of titanium oxide. By collecting the electrons at one side of his new solar cell, and replacing them at the other with an iodide electrolyte solution, Graetzel produced an electric current.

The new so-called Graetzel cells offered a simpler and potentially cheaper way to generate solar power. (Traditional silicon cells are more complicated because they require the generation of an electric field within the silicon to carry away the liberated electrons.) And because they work in a different way, Betzel says the new cells offer other advantages too. They work better in low light levels, including indoors, he says, and they are lighter and less fragile than silicon cells, which are usually mounted on glass or rigid plastic.

At least one big hitter in the renewable energy industry agrees with him: Bob Hertzberg, founder of venture capital firm Renewable Capital, a backer of the G-Wiz electric car, has invested in G24i and talks of it making annual profits of £130m within five years. The company has not yet found a major buyer for its technology, but Betzel says there are some in the wings.

Design students have also been involved with the development process. Earlier this year, the company ran a competition with 45 product design students at St Martin's college of art and design in London, who were asked to think up new uses for the Cardiff solar cells. The winning entries include portable safety lights mounted on life buoys, and lamps to mark scaffolding and hoardings around roadworks and on building sites. They also featured solar-powered security lights, fire exit signs, and window blinds, which could cut electricity use.

The first commercial uses are likely to be in the developing world, where access to electricity is difficult. The firm is working with mobile phone companies including Nokia and Motorola to test whether the G24i cells could charge handsets in rural Africa. For £6-£8, he says, the company can supply a flexible strip of solar cells that can produce 0.4 to 0.5W of power. It's a relatively meagre output, but more than enough for at least 10 minutes of phone calls a day. And that, says Betzel, can make a big difference. "Over two billion people live without access to energy. This isn't about providing expensive, Rolls Royce- quality solutions. It's about improving their quality of life." Similar solar chargers made of silicon cost about £30.

The company believes its technology is also suited to those who work in remote places where access to electricity is unreliable, such as by providing low-cost and lightweight power, lighting and water purification for the disaster relief and emergency services. It is also developing wearable "smart" fabrics, into which the solar cells have been woven, and which could be used to charge connected electronic devices. These can be made in a variety of patterns, the company's PR material notes, including camouflage. Unsurprisingly, the military is another of its target markets.

Jim Watson, deputy director of the Sussex Energy Group at the University of Sussex, is cautiously optimistic about the technology: "It takes a long time for people to take up this kind of technology, but if it works and it's cheap enough, it could play a part."

Watson says solar cell technology is likely to remain targeted at niche applications for the foreseeable future, and is more suited to preventing additional carbon emissions from the proliferation of electronic devices, rather than cutting emissions from existing sources. "What's good about that approach is that it takes renewable technologies into the consumer market, and if they can be presented in that way, they help to get the message across."

In time, G24i envisages companies being forced to "account for their carbon footprint and offset power usage", which it argues its solar technology can help them achieve. Betzel envisages large buildings hanging coloured flexible ribbons of the company's solar cells down the centre of large atria in future. He says there is no reason why the technology couldn't replace PV solar panels on the roofs of homes and other buildings, though the company has not yet proven the longevity of such large versions.

It also claims its technology will "put an end to dead batteries". There is still some way to go - the Cardiff factory's entire annual output of solar cells currently generates just 30MW, about the same as a handful of modern wind turbines (although it plans to expand to 200MW capacity next year). But Betzel insists that solar power is now a viable mass-market future technology. If he is right, then Wales may soon have an unlikely new export.